In the smelting process, due to improper ingredients or charging and excessive decarburization and other reasons, sometimes the carbon content in the steel does not meet the requirements of the top period, and then carbon is added to the molten steel. Commonly used recarburizers are recarburized pig iron, electrode powder, petroleum coke powder, charcoal powder and coke powder. When smelting medium and high carbon steel grades in a converter, petroleum coke with few impurities is used as a recarburizer. The requirement for the recarburizer for top-blown converter steelmaking is to have high fixed carbon, low ash, volatile, and sulfur, phosphorus, nitrogen and other impurities, and be dry, clean, and moderate in particle size. Medium temperature asphalt

Its fixed carbon components are:

w(C)>96%, volatile matter≤1.0%, w(S)≤0.5%, w(moisture)≤0.55%, particle size is 1 to 5mm.

If the particle size is too fine, it will burn easily, and if it is too coarse, it will float on the surface of the molten steel and will not be easily absorbed by the molten steel. The particle size of induction furnace is 0.2-6mm, of which steel and other ferrous metals are 1.4-9.5mm, high-carbon steel requires low nitrogen, and the particle size is 0.5-5mm, etc. Specific requirements for smelting workpieces according to specific furnace types Specific judgment and selection of the details and so on.

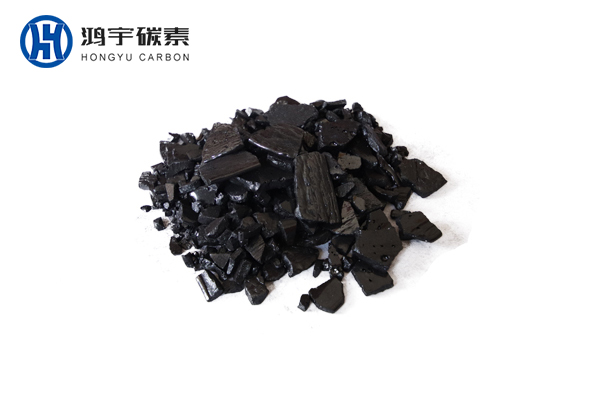

Calcined coke recarburizer

1. Furnace input method:

The recarburizer is suitable for smelting in an induction furnace, but the specific use varies according to the process requirements.

(1) The recarburizer used in the smelting of the intermediate frequency electric furnace can be added to the middle and lower parts of the electric furnace according to the proportion or carbon equivalent requirements, and the recovery rate can reach more than 95%;

(2) If the amount of carbon is not enough to adjust the carbon content, first clean the slag in the furnace, then add a recarburizer, heat up the molten iron, electromagnetic stirring or manual stirring to dissolve and absorb the carbon, and the recovery rate can be about 90%. Low-temperature recarburization process is adopted, that is, only part of the charge is melted. When the molten iron temperature is low, all the recarburizers are added to the molten iron at one time, and at the same time, the solid charge is used to press it into the molten iron to prevent it from exposing the iron. Liquid surface. This method can increase the carbon content of molten iron by more than 1.0%.

Calcined coke recarburizer processing

2. Carbon increase outside the furnace:

(1) Spray graphite powder in the bag

Graphite powder is selected as the recarburizer, and the blowing volume is 40kg/t, which is expected to increase the carbon content of the molten iron from 2% to 3%. As the carbon content of the molten iron gradually increases, the carbon utilization rate decreases. The temperature of the molten iron before the recarburization is 1600°C, and the average after the recarburization is 1299°C. Injecting graphite powder to increase carbon, generally uses nitrogen as a carrier, but under industrial production conditions, it is more convenient to use compressed air, and the oxygen in the compressed air burns to produce CO. The heat of chemical reaction can compensate for part of the temperature drop, and the reducing atmosphere of CO is conducive to Improve the carbon effect.

(2) Use recarburizer when tapping iron

The 100-300 mesh graphite powder recarburizer can be put into the bag, or flushed from the iron tapping tank with the flow. After the molten iron is discharged, stir it fully to dissolve and absorb the carbon as much as possible. The carbon recovery rate is about 50%.

For casting, cast iron, cast steel, and castings, there is a requirement for carbon. Then the recarburizer, as the name suggests, is to increase the carbon content in the molten iron. For example, the commonly used furnace materials in smelting are pig iron, scrap steel, and recycled materials. The carbon content of pig iron is high, but the purchase price is higher than that of scrap steel. Therefore, increasing the amount of scrap steel, reducing the amount of pig iron, and adding recarburizers can play a role in reducing the cost of castings to a certain extent.